Tattooing has evolved from ancient manual techniques into a refined craft powered by advanced machines. Today, tattoo machines are the foundation of professional tattooing, offering precision, consistency, and efficiency. Whether you're an artist or a curious enthusiast, understanding how these machines work deepens your appreciation of the art and the technology behind it.

Rotary Machines

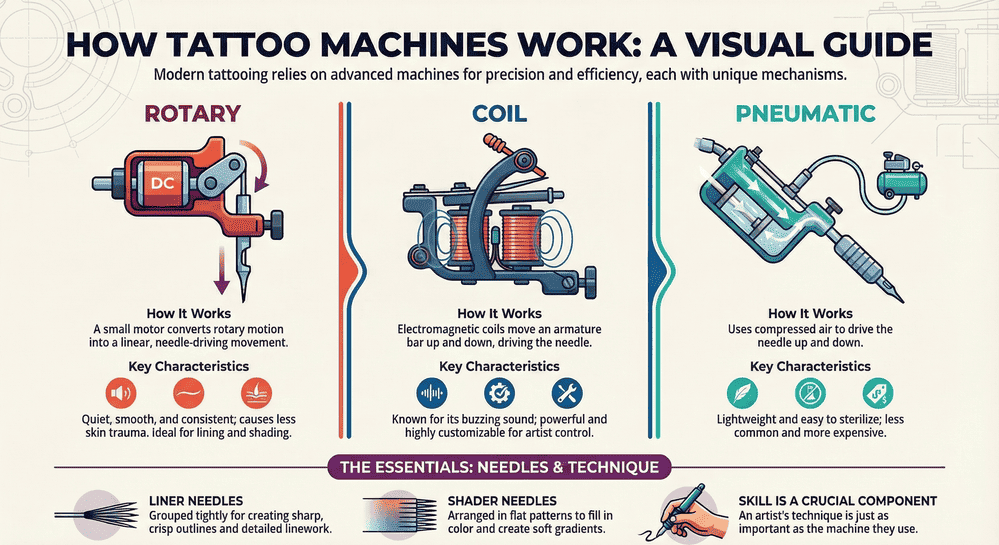

Rotary tattoo machines operate with a small motor that converts rotary motion into linear movement. This motion drives the needle smoothly and consistently, resulting in quieter operation and less skin trauma. Ideal for both lining and shading, rotary machines require minimal maintenance and are favored for long sessions due to their consistent performance and ergonomic design.

Coil Machines

Coil tattoo machines are traditional tools that use electromagnetic coils to move an armature bar up and down. This motion drives the needle into the skin. They are known for their buzzing sound and are ideal for both linework and shading. Many artists prefer coil machines for their power, customizability, and control.

Pneumatic Machines

Pneumatic tattoo machines use compressed air to drive the needle. Lightweight and easy to sterilize, they’re ideal for hygienic environments and long tattoo sessions. While less common and more expensive, they offer advanced control and reduced fatigue for artists.

Core Components and How They Work

The central mechanism in a tattoo machine—whether rotary, coil, or pneumatic—is the movement of the needle. In coil machines, it's electromagnetic; in rotary and pneumatic, it's motorized or air-driven. This motion punctures the skin to deposit ink in the dermis.

The grip and tube house the needle and ensure control and comfort. An external power supply controls voltage and speed, often with a footswitch for hands-free operation.

Needle Types and Their Purpose

Liner needles are grouped tightly for sharp outlines, while shader needles are arranged in flat or magnum patterns to fill in color and create soft gradients. Artists select needles based on the technique, design, and effect they want to achieve.

Technique Matters

The artist’s skill is as important as the machine itself. Artists stretch the skin, guide the needle with steady motion, and adjust depth and speed. Years of practice allow professionals to master their machines and produce intricate, high-quality artwork.

A Brief History

Inspired by Thomas Edison’s electric pen, the first tattoo machine was developed in the late 1800s. Over time, machines became lighter, more efficient, and more precise—evolving into the advanced tools artists use today.

Conclusion

Tattoo machines are the backbone of modern tattooing. Understanding the different types, components, and techniques not only helps artists improve their skills but also gives clients a greater appreciation of the art form. From classic coil machines to modern pneumatic tools, tattoo machines continue to shape the evolution of tattooing.