The Complete Guide to Tuning VladBlad Irons Coil Tattoo Machines

A finely tuned tattoo machine is like a musical instrument — smooth, precise, and responsive. Whether you're a seasoned pro or just starting out, knowing how to tune your VladBlad Irons coil machine is essential for producing clean, consistent tattoos. This guide breaks down everything you need to achieve optimal performance.

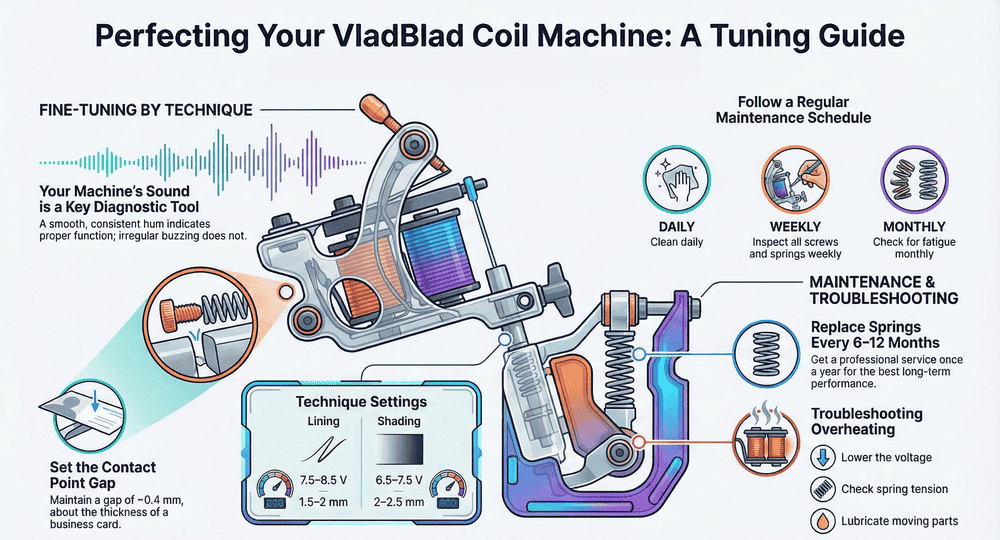

Understanding the Sound of a Well-Tuned Machine

Your machine’s sound is your first diagnostic tool. A consistent, smooth hum means it's functioning properly. Irregular buzzing, skipping, or harsh vibrations? Those are red flags that adjustments are needed. Likewise, uneven linework or weak saturation often indicate tuning issues.

Setup: Clean, Check, and Test

Start with a clean, organized workstation. Wipe down your machine, check all screws, and inspect contact points. Even minor buildup or loose components can impact performance.

Paper Test: Run your machine across a white sheet. You should see smooth, consistent lines without skipping or drag. The needle should move in a straight path with no wobble. Listen for a steady hum at all angles.

Key Technical Adjustments

Voltage & Frequency

- Lining: 7.5–8.5V @ ~125 Hz — for crisp, bold lines.

- Shading: 6.5–7.5V — for softer gradients.

Start with small voltage changes (0.2–0.3V) and listen for a clean, uninterrupted sound.

Contact Point

Maintain a gap the thickness of a business card (~0.4 mm) between the armature bar and front spring.

Amplitude

- Lining: 1.5–2 mm

- Shading: 2–2.5 mm

Spring Tension

The front spring should allow a quick needle return without excessive force, while the back spring stabilizes the motion. Check regularly for wear and tension.

Pre-Session Checklist

- Test at working voltage

- Listen for consistency

- Check armature movement

- Tighten all screws

- Clean contact points

Monitor performance during tattooing — overheating or sound changes may require adjustments.

Fine-Tuning by Technique

Lining

Use higher voltage and firmer spring tension for sharp outlines. Fast, hard hits are key.

Shading

Lower voltage and soften spring tension. Aim for slower, smoother hits for blending.

Maintenance: Keep It Running Strong

Daily

Clean the machine, especially around the armature bar and contact points.

Weekly

Inspect all screws, springs, and connections. Lubricate if needed.

Monthly

- Check springs for fatigue

- Inspect contact points and frame

- Ensure electrical integrity and band tension

Troubleshooting Common Issues

- Overheating: Lower voltage, check spring tension, lubricate moving parts.

- Inconsistent hits: Check alignment, contact screw, and needle bar movement.

- Vibration: Tighten frame, balance springs, inspect alignment.

Track Your Settings

Keep notes on:

- Voltage by technique

- Contact screw placement

- Spring tension

- Needle types

Long-Term Care

Store your machine in a dry case. Replace springs every 6–12 months. Get a professional service once a year for best performance.

Final Thoughts

Your VladBlad Irons machine is your most reliable tool. Tune it properly, maintain it regularly, and it will reward you with clean lines, smooth shading, and consistent performance — every time.