Types of tattoo machines

Historical Evolution of Tattoo Machines

Tattooing started as a manual practice using primitive tools. In 1891, Samuel O'Reilly revolutionized the craft with the electric tattoo machine, based on Edison’s electric pen. This greatly improved speed and precision. The coil machine, introduced in 1929 by Percy Waters, became the industry standard, followed by quieter and more ergonomic rotary machines in the 1970s. The 2000s brought pen-style and wireless machines, expanding the range of tools available to artists.

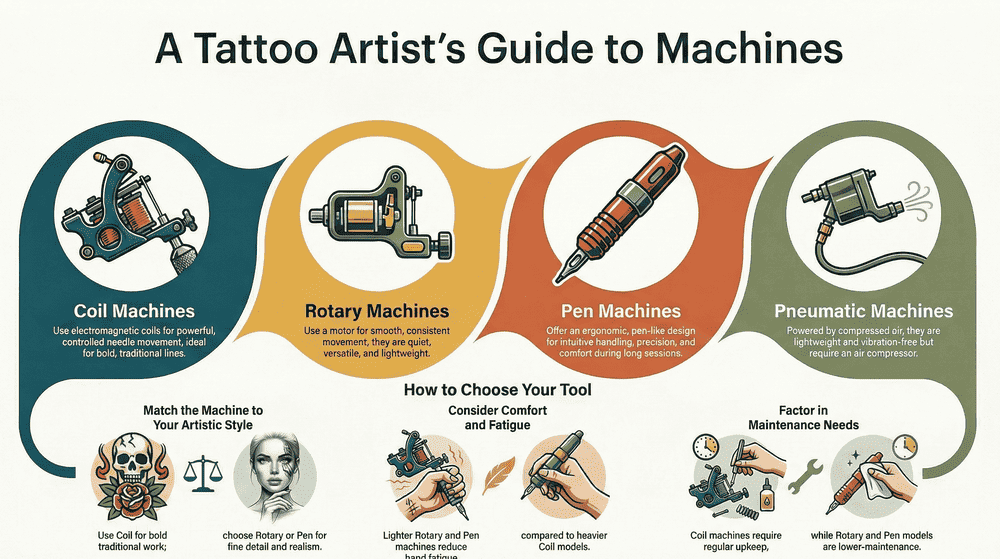

Types of Tattoo Machines

Coil Tattoo Machines

Known for their power and control, coil machines use electromagnetic coils to move the needle. They provide strong feedback, making them ideal for bold lines and traditional tattoos. However, they can be heavy and noisy.

Rotary Tattoo Machines

Rotary machines use a motor for smooth, consistent needle movement. They’re quieter, lighter, and versatile, making them suitable for both lining and shading. They require less maintenance and reduce hand fatigue.

Pen Tattoo Machines

Pen-style machines offer an ergonomic, pen-like design that’s intuitive and easy to handle. Often wireless, they provide precision and comfort, especially for detailed work and long sessions.

Pneumatic Tattoo Machines

Powered by compressed air, pneumatic machines are lightweight and vibration-free. They stay cool during long sessions and are favored for their accuracy, though they require an air compressor setup.

Ultron Series

Includes Ultron Pen, Ultron 2 & 3 Series, and their custom versions. These high-end machines focus on ergonomics, precision, and reliability, ideal for professionals seeking premium performance.

How to Choose the Right Tattoo Machine

- Artistic Style: Choose coil for bold lines and traditional work; rotary or pen for fine detail and realism.

- Comfort: Consider weight, balance, and grip. Lighter machines reduce fatigue.

- Maintenance: Coil machines need more upkeep; rotary and pen models are lower-maintenance.

- Power: Coil machines may require stronger power supplies; rotary and pen machines are generally more adaptable.

Tattoo Machine Maintenance

- Clean after each use: Remove ink, skin particles, and sanitize properly.

- Lubricate moving parts: Prevent wear and ensure smooth performance.

- Inspect components: Check for worn parts, such as springs, o-rings, and bearings.

- Replace parts as needed: Keep a log to track replacements and service intervals.

- Store safely: Protect from dust, moisture, and physical damage using cases.

Conclusion

Understanding tattoo machines is key to achieving consistent, high-quality results. Whether you prefer the raw power of a coil machine or the comfort of a rotary or pen device, the right tool supports your technique and helps elevate your craft. Prioritize functionality, comfort, and reliability—and maintain your equipment to ensure long-term success as a tattoo artist.